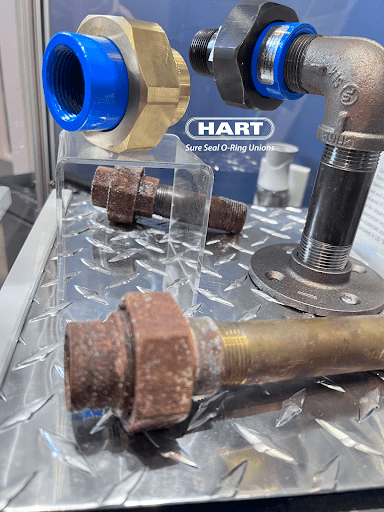

One of HART Industrial Unions’ specialties is in production of dielectric insulated carbon steel unions ideal for petroleum and natural gas applications. Our dielectric insulated O-ring unions for these sectors create a reliable flow point with a seal that won’t break down, even during high-pressure applications or after constant exposure to corrosive petroleum and natural gasses. HART produces all of our carbon steel unions in the U.S. to guarantee quality materials and construction, and reliable final parts in the face of vibration, turbulence, corrosive substrates, high pressures, and more. We use precision machining and assembly techniques so every union is a perfect fit.

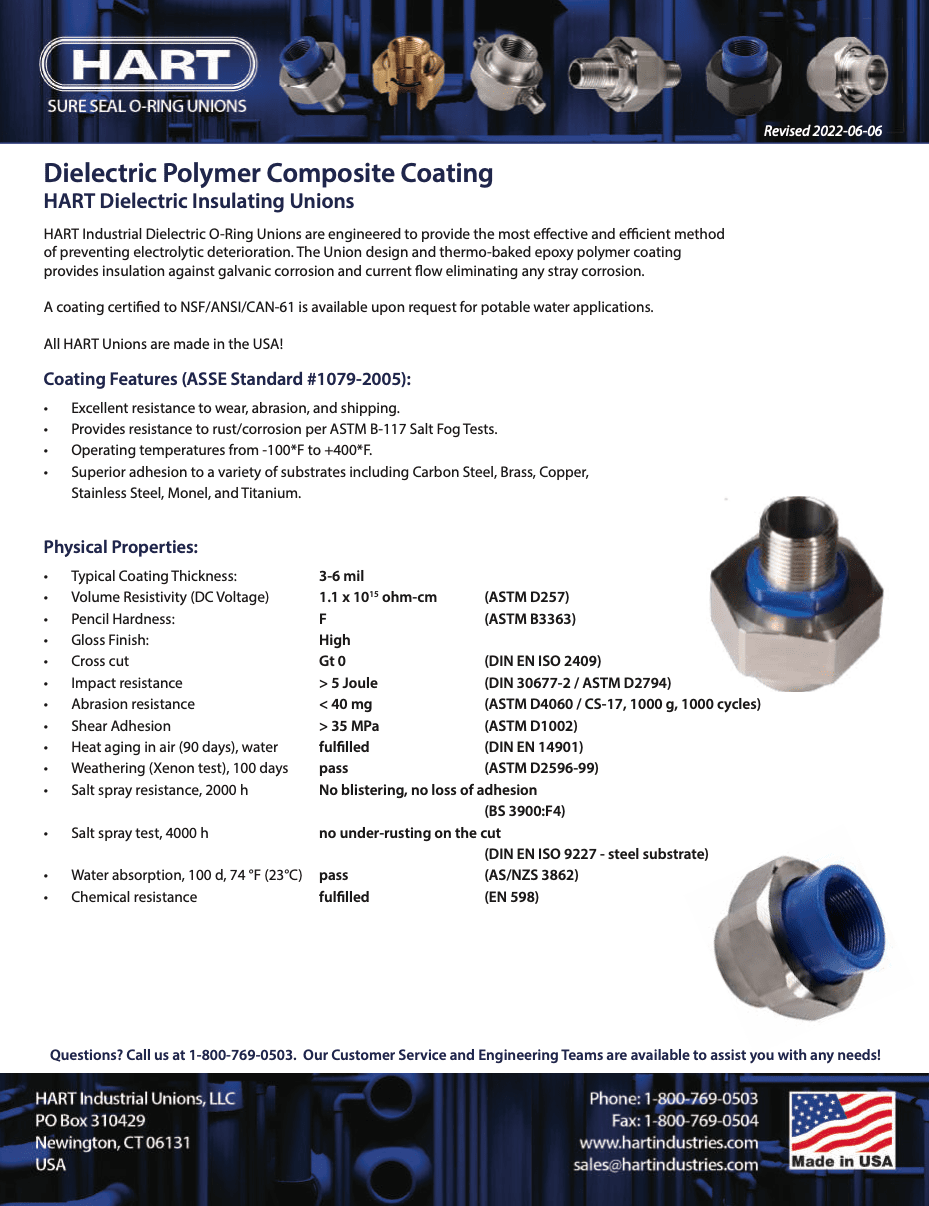

HART Dielectric Insulating Coating – Technical Data Sheet.pdf

HART Dielectric Petroleum and Natural Gas Unions.pdf

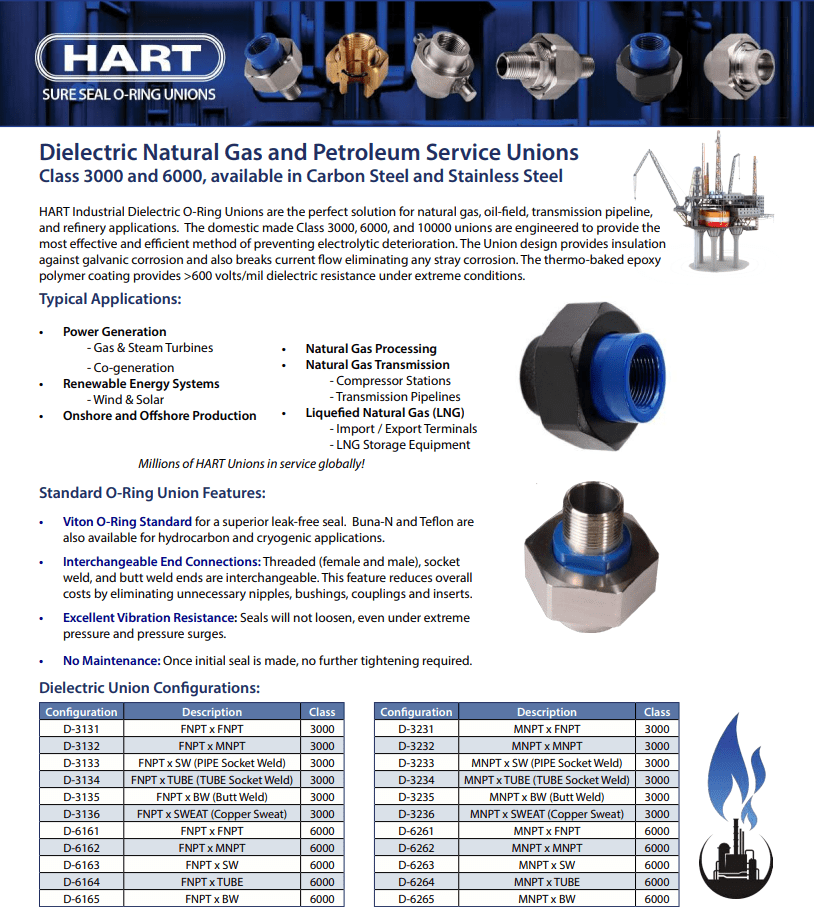

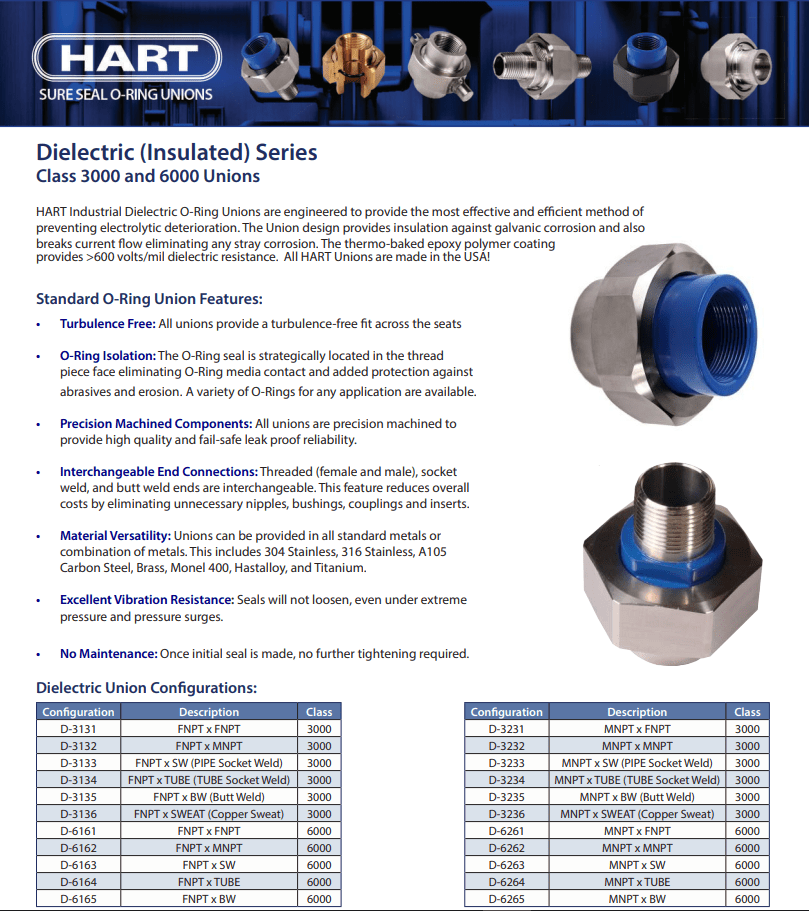

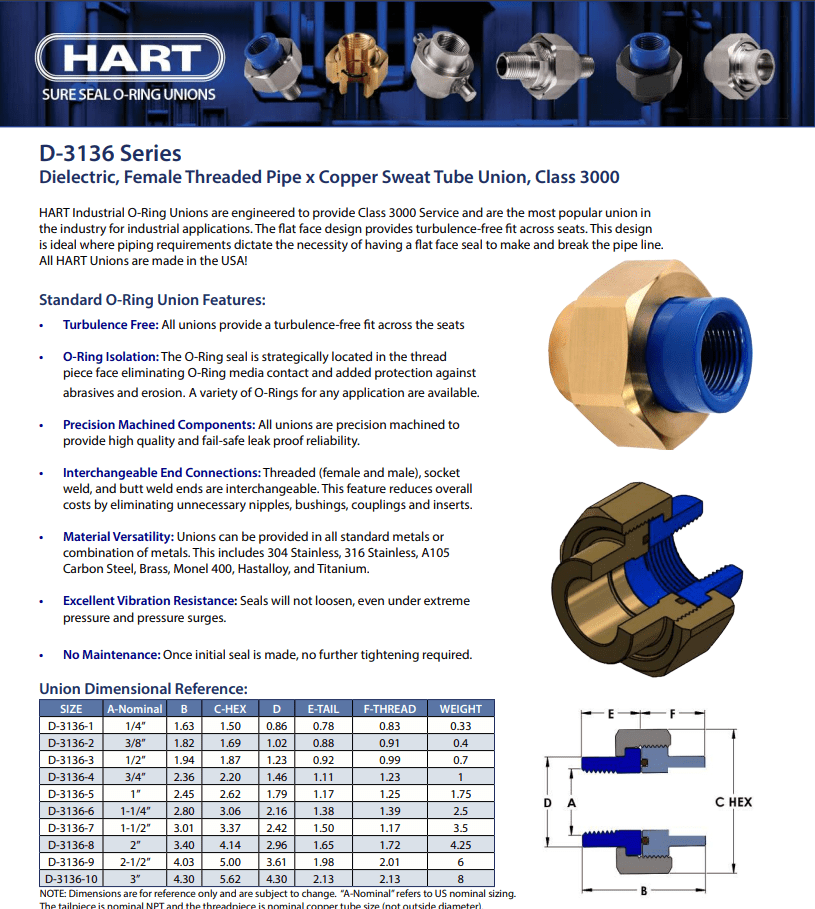

HART Industrial Dielectric Insulated O-Ring Unions are the perfect solution for natural gas, oil-field, transmission pipeline, and refinery applications. The domestic made Class 3000, 6000, and 10000 unions are engineered to provide the most effective and efficient method of preventing electrolytic deterioration. The Union design provides insulation against galvanic corrosion and also breaks current flow eliminating any stray corrosion.

The thermo-baked epoxy polymer coating provides >600 volts/mil dielectric resistance under extreme conditions. Unions can be provided with any connection type on the threadpiece side (welded, sweat, threaded, etc) and can be made to transition between different piping sizes!

HART O-Ring Union Features:

- Turbulence Free: All unions provide a turbulence-free fit across the seats

- O-Ring Isolation: The O-Ring seal is strategically located in the thread

piece face eliminating O-Ring media contact and added protection against abrasives and erosion. A variety of O-Rings for any application are available. - Precision Machined Components: All unions are precision machined to provide high quality and fail-safe leak proof reliability.

- Interchangeable End Connections: HART’s male threaded connections feature interchangeable configurations with other threaded or welded connections, reducing the need for nipples or additional fittings.

- Material Versatility: Unions can be provided in all standard metals or combinations of metals. This includes 304 Stainless, 316 Stainless, A105 Carbon Steel, Brass, Monel 400, Hastelloy, and Titanium.

- Excellent Vibration Resistance: Seals will not loosen, even under extreme pressure and pressure surges.

- No Maintenance: Once the initial seal is made, no further tightening is required.

-

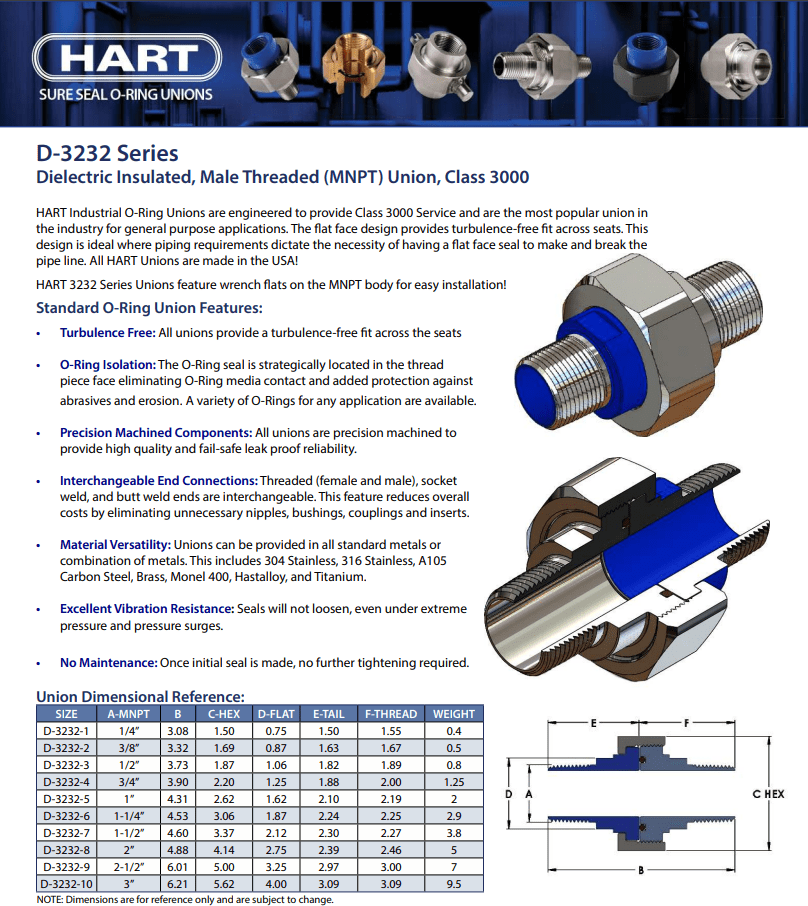

Specifications

Configuration Description Class D-3131 FNPT * FNPT 3000 D-3132 FNPT * MNPT 3000 D-3133 FNPT * SW (Pipe Socket Weld) 3000 D-3134 FNPT * TUBE (Tube Socket Weld) 3000 D-3135 FNPT * BW (Butt Weld) 3000 D-3136 FNPT * SWEAT (Copper Sweat) 3000 D-6161 FNPT * FNPT 6000 D-6162 FNPT * MNPT 6000 D-6163 FNPT * SW 6000 D-6164 FNPT * TUBE 6000 D-6165 FNPT * BW 6000 Configuration Description Class D-3231 MNPT * FNPT 3000 D-3232 MNPT * MNPT 3000 D-3233 MNPT * SW (Pipe Socket Weld) 3000 D-3234 MNPT * TUBE (Tube Socket Weld) 3000 D-3235 MNPT * BW (Butt Weld) 3000 D-3236 MNPT * SWEAT (Copper Sweat) 3000 D-6261 MNPT * FNPT 6000 D-6262 MNPT * MNPT 6000 D-6263 MNPT * SW 6000 D-6264 MNPT * TUBE 6000 D-6265 MNPT * BW 6000 - 3D Animations

- Datasheets

The petroleum and natural gas industries use dielectric insulated unions throughout a range of mining and processing stages. Some of the most common applications for our carbon steel and other dielectric insulated unions include the following:

- Liquefied natural gas (LNG). We have the experience and expertise to create trustworthy unions and seals for import/export terminals and storage equipment that resist LNG corrosion and degradation. Even for gas applications, the O-ring stays tight and won’t require additional maintenance.

- Natural gas processing and transmission. These unions can mitigate the risks of turbulence and vibration under high-pressure situations and sudden pressure surges. With a fail-safe seal, our unions mitigate leaks, chemical corrosion, and degradation in compressor stations or transmission pipelines.

- Oil fields. HART builds dielectric O-ring unions from a wide range of sturdy metals and sealing material options to withstand the constant flow of corrosive petroleum, natural gas, hydrocarbons, and other chemicals.

- Onshore and offshore production. Corrosion is a leading factor in transmission pipeline failure, so our erosion-resistant Sure Seal O-ring dielectric unions are ideal for on- and offshore applications.

- Power generation. The dielectric capabilities of our carbon steel unions are well suited for power generation applications such as steam and gas turbines or co-generations.

- Renewable energy systems. Our unions’ combination of dielectric insulation and durability makes them a perfect fit for solar and wind energy in the renewable energy sector.

HART Industrial Unions’ Capabilities

At HART Industrial Unions, we specialize in designing and developing dielectric insulated unions for natural gas, petroleum, and other industrial processes. Some carbon steel products can be difficult to source, and we at HART pride ourselves on our full line of carbon steel dielectric unions. In addition to our dielectric insulated unions, HART also offers male and female threaded unions, hammer lug unions, orifice unions, and many other fitting types to suit your needs.

To learn more about our Engineering and Manufacturing Capabilities, visit our CAPABILITIES

With rapid turn times and our expanded capacity for supporting our customers’ requirements for high-pressure pipe unions, we are here to help. Contact us today to learn more about our products or to start your order