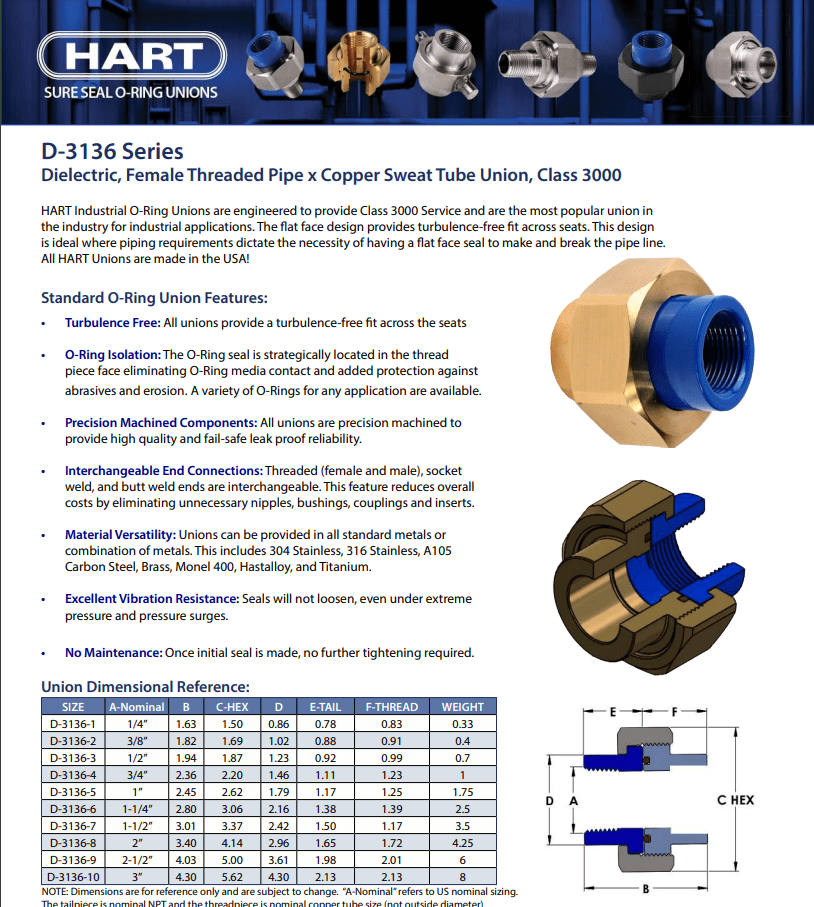

HART Industrial Unions offers a wide range of welded connection styles, including copper sweat tube unions. Copper sweat unions are used as a permanent, sweated (or brazed) connection between two copper tubes or tubing systems. HART Industrial Unions has the capability to manufacture standard and customized copper sweat unions suitable for K, L and M style copper tubing in Class 3000 and Class 6000 applications.

HART Industrial Unions offers a wide range of welded connection styles, including copper sweat tube unions. Copper sweat unions are used as a permanent, sweated (or brazed) connection between two copper tubes or tubing systems. HART Industrial Unions has the capability to manufacture standard and customized copper sweat unions suitable for K, L and M style copper tubing in Class 3000 and Class 6000 applications.

Copper Sweat unions are expressed in nominal copper tubing size (e.g. 1” Copper Sweat mates with 1-inch copper tubing which is 1.125” O.D.).

HART’s copper sweat connections are typically manufactured using brass and are interchangeable with other HART welded and threaded connection styles. Brass 464 (Naval Brass) is available to meet lead-free requirements. For marine or high-saltwater / corrosive applications, 70-30 and 90-10 Copper-Nickel are available upon request.

HART O-Ring Union Features:

- Turbulence Free: All unions provide a turbulence-free fit across the seats

- O-Ring Isolation: The O-Ring seal is strategically located in the thread

piece face, eliminating O-Ring media contact and added protection against abrasives and erosion. A variety of O-Rings for any application are available. - Precision Machined Components: All unions are precision machined to provide high quality and fail-safe leak proof reliability.

- Interchangeable End Connections: HART’s male threaded connections feature interchangeable configurations with other threaded or welded connections, reducing the need for nipples or additional fittings.

- Material Versatility: Unions can be provided in all standard metals or combinations of metals. This includes 304 Stainless, 316 Stainless, A105 Carbon Steel, Brass, Monel 400, Hastelloy, and Titanium.

- Excellent Vibration Resistance: Seals will not loosen, even under extreme pressure and pressure surges.

- No Maintenance: Once the initial seal is made, no further tightening is required.

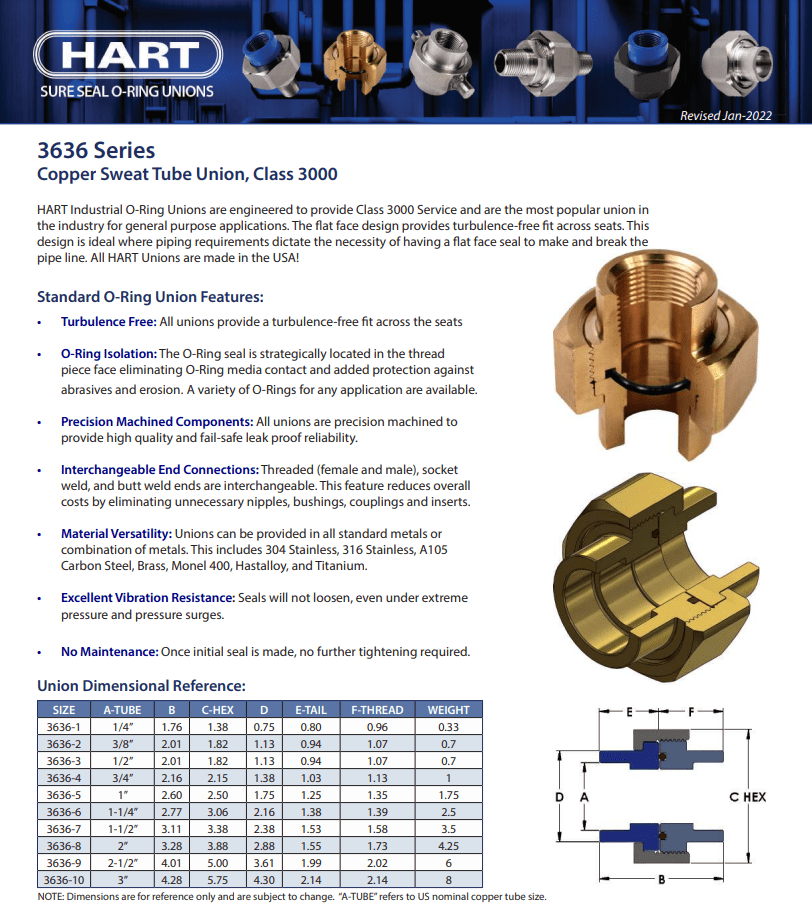

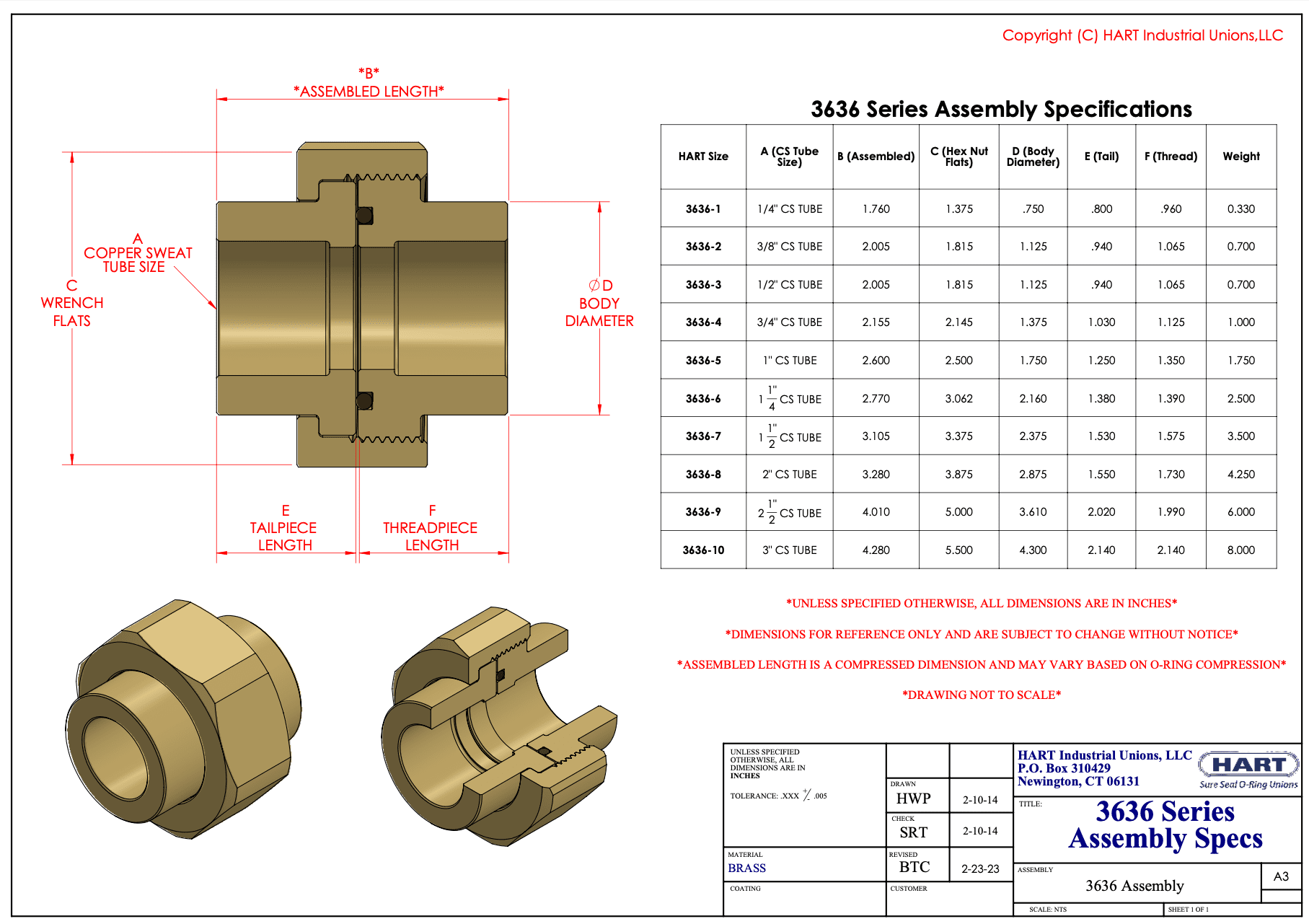

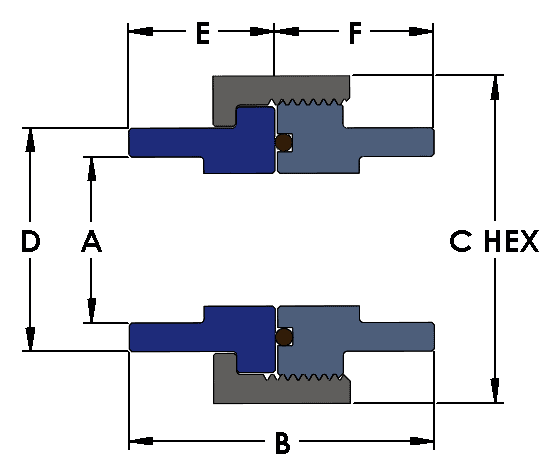

3636 Series Copper Sweat, Class 3000

-

Specifications

SIZE A-TUBE SIZE B C-HEX D E-TAIL F-THREAD WEIGHT

(LBS)3636-1 1/4 1.76 1.38 0.75 0.80 0.96 0.33 3636-2 3/8 2.01 1.82 1.13 0.94 1.07 0.7 3636-3 1/2 2.01 1.82 1.13 0.94 1.07 0.7 3636-4 3/4 2.16 2.15 1.38 1.03 1.11 1 3636-5 1 2.60 2.50 1.75 1.25 1.35 1.75 3636-6 1-1/4 2.77 3.06 2.16 1.38 1.39 2.5 3636-7 1-1/2 3.11 3.38 2.38 1.53 1.58 3.5 3636-8 2 3.28 3.88 2.38 1.55 1.73 4.25 3636-9 2-1/2 4.01 5.00 3.61 1.99 2.02 6 3636-10 3 4.28 5.75 4.30 2.14 2.14 6 - 3D Animations

- Datasheets

- HVAC and Coolant Loops

- Water Delivery Systems

- Piping systems, especially those that need to meet tight regulatory requirements or specifications

- Plumbing systems with weldable components

- Highly sensitive processing and transportation applications that cannot permit any risk of a potential leak, typically involving flammable, expensive, or toxic fluids

HART Industrial Unions’ Capabilities

At HART Industrial Unions, we design and construct high-pressure and specialty unions for a wide variety of piping and tubing system applications. We build our copper sweat unions to last with superior resistance to vibration, turbulence, and erosion. HART constructs unions from a vast selection of metals and fitting options to create the perfect fit, including stainless and carbon steel, aluminum, Hastelloy, and Monel 400.

We make our precision-machined components in the USA, including our comprehensive line of Sure Seal O-rings. Found on the face of a thread piece, these O-rings reduce media contact in joints and ensure a reliable, fail-safe seal for your systems.

To learn more about our Engineering and Manufacturing Capabilities, visit our Capabilities.

Contact us today to learn more about our selection of socketweld unions or to request a quote.

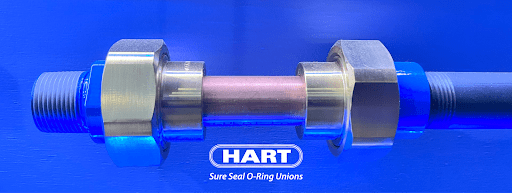

HART Copper Sweat Unions

HART Copper Sweat Unions